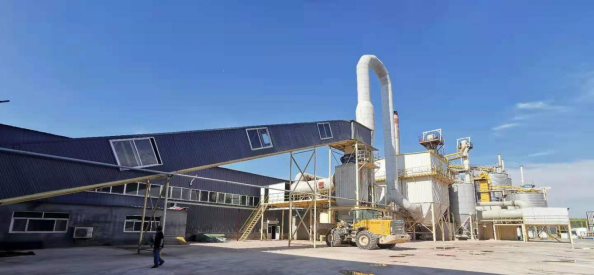

Gypsum powder production line calcination system ---Introduction of boiling furnace

The gypsum powder production line generally adopts the method of pulverization and calcination. The natural gypsum and by-product gypsum are made into gypsum powder. the calcination system is very important for the entire production line. Commonly used in the market are: boiling furnace; chamber calcining; tubular rotary kiln; multi-channel composite gypsum calcining kiln; steam calcining kiln, etc.

Among them, the boiling furnace is a kind of traditional calcination equipment that is widely used. It is generally divided into three types: oil heating type, air heating type and steam heating type; this equipment is a vertical calcination equipment, and there are a large number of heat exchange pipes inside the equipment. Heat medium (heat transfer oil, high temperature flue gas, high pressure steam) is introduced into it.

There is an air distribution board at the bottom of the equipment, the fan blows a certain amount of air to make the gypsum layer in a fluid state, and the steam generated by the heat exchange between the gypsum and the heat pipe makes the gypsum in a boiling state, and the gypsum in the fluid state is dehydrated and then enters the separator After another area, it enters the overflow outlet in the upper part of the bed.

The boiling furnace has a simple structure, low investment in main equipment, compact equipment and small footprint. It is the main calcination system promoted by our company, which helps customers save investment, reduce land occupation and produce high-quality gypsum powder.

We Beixin Machinery has been deeply engaged in the field of gypsum machinery complete sets of equipment for more than 30 years.

We have the ability to provide you with professional design and high-quality production line complete sets of equipment to help you build a plaster powder factory and produce high-quality gypsum powder. Look forward to working with you.