The Importance of Natural Gypsum Ore And Gypsum Powder Testing

Building gypsum is a powdered cementitious material obtained by dehydration of natural mineral gypsum or industrial by-product gypsum, with calcium sulfate hemihydrate (CaSO4·½H2O) as the main component. According to the types of raw materials, it is mainly divided into: natural building gypsum, desulfurized building gypsum and phosphorus building gypsum.

Building gypsum can be made into cooked gypsum powder through the gypsum powder production line, which is the main raw material for making gypsum board.

Natural gypsum ore

Gypsum powder is the main raw material for gypsum board production. If you buy gypsum powder, each batch needs to be tested before being put into production. Otherwise, there will be problems with the quality of gypsum board, which will cause cost waste and it is difficult to find out the reasons.Therefore, the factory will have its own gypsum powder testing laboratory.

Laboratory testing for gypsum powder

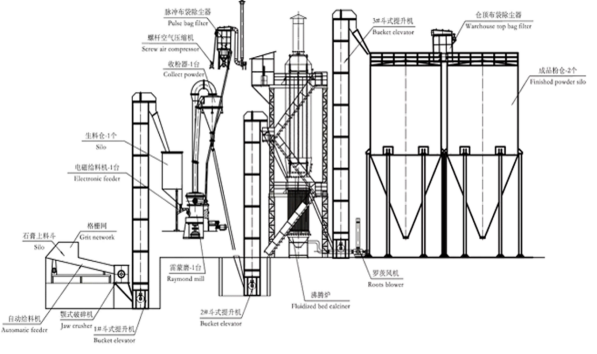

If the raw material is natural gypsum ore, it is necessary to detect the composition of gypsum ore to confirm whether it meets the standard of gypsum board raw materials, and then build a gypsum powder production line to make natural gypsum stone into gypsum powder.

Process flow of gypsum powder production line

Our engineers can check the gypsum ore inspection report for you to help customers confirm whether they meet the gypsum board raw material standards.

Customer Natural Gypsum Ore Test Report

Beixin Machinery has been focusing on gypsum machinery manufacturing and R&D for more than 30 years, providing customers with one-stop service and helping customers build complete gypsum powder and gypsum board factory.

Gypsum Powder Factory case